PVC pipe making machine, PVC pipe extrusion machine, PVC pipe production line

Description PVC pipe making machine:

This set is composed of conical twin-screw extrude, vacuum calibration tank, haul-off machine, cutter, stacker etc. The screw extruder and traction machine adopt imported AC frequency control device. The vacuum pump and traction motor both adopt advanced products. The haul-off machine has many models, such as two-claw, three-claw, four-claw, six-claw etc. It may choose visual blade or cutting type.The unit is of reliable performance and high production efficiency.

At present, in China the plastic pipe production capacity of 3 million tons, mainly PVC, PE and PP-R pipeline three categories, of which PVC pipe market share is the largest plastic pipe, plastic pipe accounted for nearly 70% of the share.

PVC pipe making machine process

Production Process Raw Material + Additive Preparation → Mixing → Feeding → Conical Twin Screw Extruder → Extrusion Mold → Vacuum Forming Tank → Crawler Haul-Off → Lifting Cutter → Stacker → Completed Product Inspection & Packaging

Video of PVC pipe making machine, PVC pipe extrusion machine, PVC pipe production line

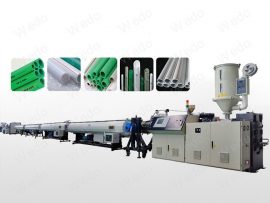

Photos PVC pipe making machine, PVC pipe extrusion machine, PVC pipe production line:

Extruder machine, vacuum calibrator machine

Haul-off machine,cutting machine

PVC pipe making machine specification:

Diameter(mm) | 16-40Two Cavities | 20-63Two Cavities | 20-63 | 50-160 | 63-200 | 160-315 | 315-630 |

Models | SJZ51/105 | SJZ65/132 | SJZ51/105 | SJZ65/132 | SJZ65/132 | SJZ80/156 | SJZ92/188 |

Motor Power | 18.5AC | 37AC | 18.5AC | 37AC | 37AC | 55AC | 110DC |

Max. Linear Speed | 10 | 15 | 15 | 8 | 3.5 | 3 | 1.2 |

Max. Output | 120 | 250 | 120 | 250 | 250 | 350 | 800 |

Reviews

There are no reviews yet.