Double Shaft Plastic Shredder Machine

Description of Double Shaft Plastic Shredder:

The two-shaft shredder is a low speed and high torque industrial, thus saving energy. This dual shearing shredder does not have a screen unit. After material is fed into the hopper, material is handled using two counter rotating blades, then directly discharged. Although the output particle size is random, the two shaft shredder features a faster shredding speed and a higher throughput than other shredders.

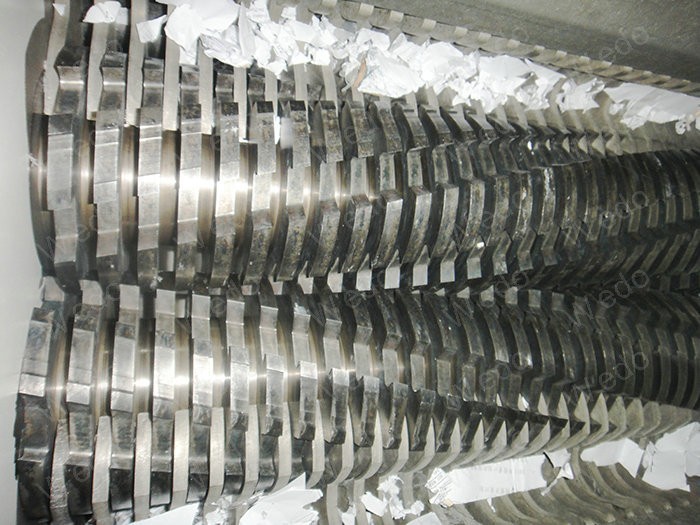

Double shaft shredder is composed of motor, hard tooth surface reducer, rotating cutter shaft, movable knife, frame, stand, box body, working platform and other main structures.

Mount fixed knife frame, rotating knife shaft is equipped with removable inserts the knife. The knife number according to the size of the different models and rotating knife shaft and decide. Can removed after using a blunt knife again, save maintenance cost greatly, increase the service life of the machine. Because it is a claw type moving blade, rotary cutting, and the knife to import SKD11 material, after heat treatment the hardness of HRC60 ° above, long service life, strong cutting ability, high capacity.

The electrical system controlled by microcomputer PLC. After the completion of commissioning, the operator can only start automatically by the F1 machine, and the F2 machine will stop automatically.

Save labor cost and ensure safe operation.

Video of double shaft shredder, shredding machine:

Photos of Double Shaft Plastic Shredder:

Application of Double Shaft Plastic Shredder:

Car tire Truck tire.

PE, PP, BOPP film, woven bag, jumbo bag, ton bag.

Fishing nets, waste fabrics.

Municipal solid waste

Agricultural waste.

Advantages Double Shaft Plastic Shredder:

Unique parallel double shaft shredding system, synchronous centripetal rotating, ensure shredding coordination and stability.

Moving knife adopts four angles structure, perfectly matched with serration fixed knife. Realize high capacity and small output size

Equipped with two independent power system, low rotation rate and high torque, avoid winding and stuck.

Electrical system adopts PLC program, features start, stop, reverse functions along with automatic overload return mechanism to prevent damage to working parts. Lower labor intensity and longer machine service life.

Technical parameters Double Shaft Plastic Shredder:

Shredder model | D600 | D800 | D1000 | D1200 | D1600 |

Shaft diameter | 275mm | 275mm | 315mm | 315mm | 350mm |

Moving knife NO. | 60 | 78 | 96 | 114 | 150 |

Fixed knife NO. | 4 | 4 | 8 | 8 | 8 |

Maximum capacity | 600kg/h | 800kg/h | 1200kg/h | 1500kg/h | 2000kg/h |

Motor power | 22KW×2 | 30KW×2 | 37KW×2 | 45KW×2 | 55KW×2 |

Host weight | 3600kg | 4000kg | 6500kg | 7500kg | 8500kg |

Chamber size | 660L×950W | 860L×950W | 1060L×1030W | 1260L×1030W | 1660L×1100W |

Dimensions | 3000L×1250W×2300H | 3200L×1250W×2350H | 3500L×1250W×2400H | 3750L×1250W×2450H | 4200L×1450W×2500H |

Reviews

There are no reviews yet.